AQUIS Coil Restoration

AQUIS Coil Restoration combines a high-performance sanitization process with an innovative probiotic technology in order to detach and eliminate biofilms from deep within coils. The result is coils that are cleaned at a microscopic level, driving increased operational efficiency, extended coil service life and improved indoor air quality.

Benefits of AQUIS Coil Restoration

- Unlocks Lost System Capacity

- Improves Indoor Air Quality

- Renews Coil Air Flow Performance

- Probiotic is Non-Corrosive to Metal Coils

- Improves Heat Transfer Efficiency & Extends Coil Service Life

- Contains Zero VOCs & No Detectable Odors

- Requires Minimal Equipment Downtime

- Utilizes a Safe & Environmentally Friendly Probiotic

The Process

Innovative Process Strips Biofilm from Coils

AQUIS Coil Restoration is a specialized process performed only by highly trained AQUIS technicians. The process utilizes an environmentally friendly probiotic technology combined with super-heated water to clean coils at a microscopic level, including eliminating biofilms.

Process Attributes

- Coil restorations are completed in just 4-8 hours, depending on AHU size.

- Eco-friendly probiotic products are classified as a Generally Recognized as Safe (GRAS) food additive.

- Probiotic agent is non-corrosive to metal coils.

- Sanitization process uses super-heated water at 280°F and 1000 psi.

- System is powered by HD-5 propane and complies with OSHA emission requirements for indoor use.

- Process is virtually odorless and is free of VOCs.

How It Works

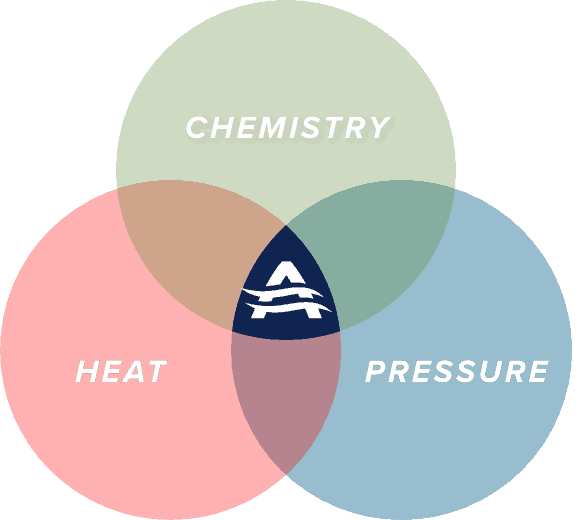

The AQUIS Coil Restoration process is designed to restore coil performance through the elimination of biofilm buildup within and throughout the coil matrix. The resilient nature of biofilms makes them very difficult to remove, and only through the combination of chemistry, heat, and pressure can biofilm-contaminated coils be comprehensively restored.

AQUIS Coil Restoration Trifecta

Chemistry

CHEMISTRY

Eco-friendly probiotics produce enzyme-containing biosurfactants which attack and dismantle biofilm.

Heat

HEAT

Steam at 280°F emulsifies and loosens stubborn biofilm throughout coils.

Pressure

PRESSURE

1000 psi water penetrates deep within coils to detach and remove biofilm completely.

CHEMISTRY + HEAT + PRESSURE

AQUIS Coil Restoration combines heat, pressure and probiotics to provide the most effective coil restoring process available.

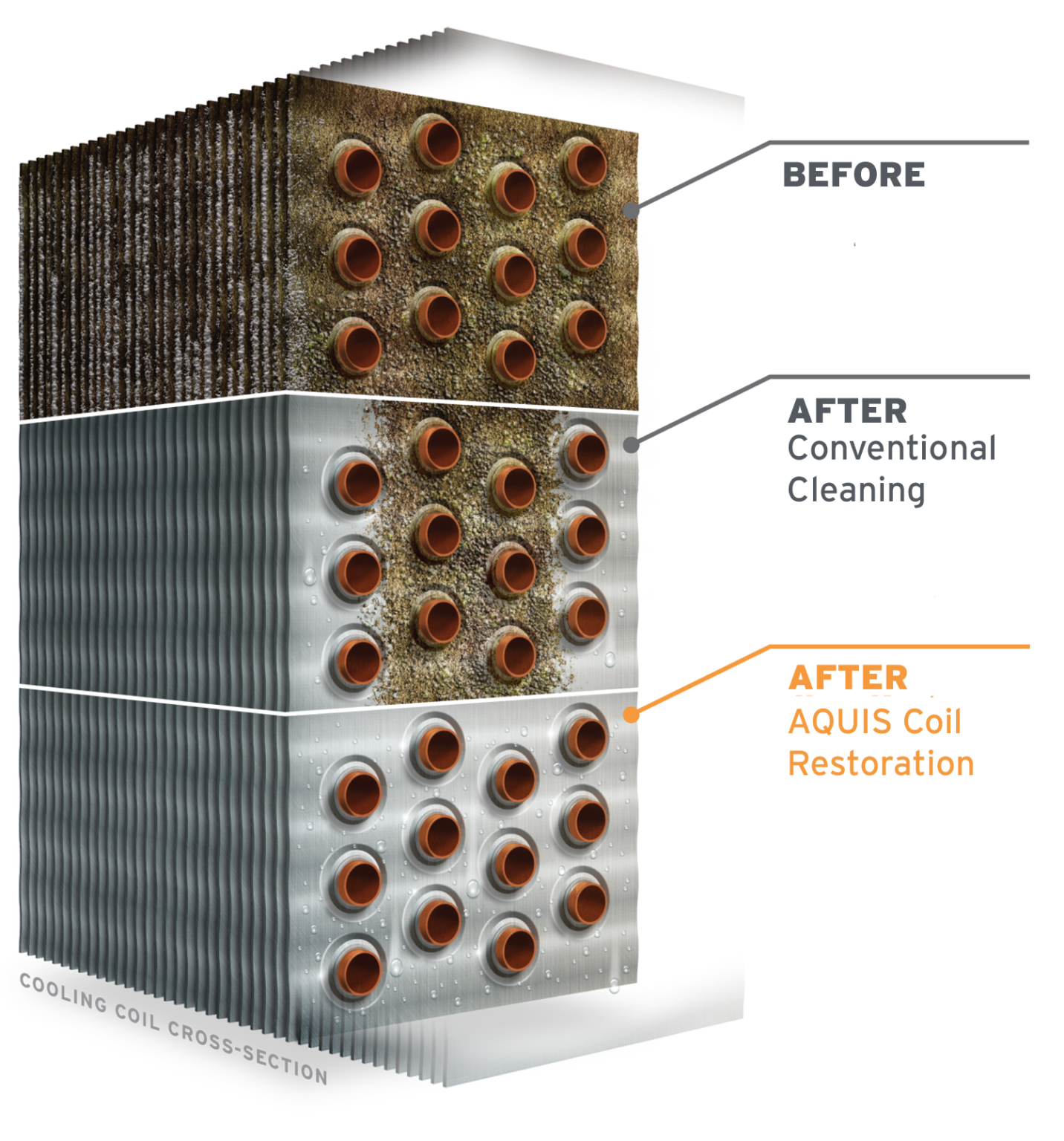

Comparison to Traditional

Traditional coil cleaning processes fail to effectively remove biofilms deep within the coil, providing only marginal improvements in coil efficiency and indoor air quality. AQUIS Coil Restoration disrupts the status-quo by combining an eco-friendly probiotic with a high-performance sanitization process to restore lost system capacity and improve coil performance.

Traditional Coil Cleaning

- Pressure washers and steam cleaners fail to penetrate and clean deep within coils

- Utilizes environmentally toxic chemicals that have strong odors and contain VOCs

- Chemicals are often corrosive to metal coils limited coil life

- Incapable of removing stubborn biofilms from coil fins

AQUIS Coil Restoration

- Super-heated water penetrates and sanitizes deep within the coils

- Utilizes an eco-friendly probiotic technology (GRAS*) that is odorless and free of VOCs

- Probiotic agent is non-corrosive to metal coils

- Loosens and removes stubborn biofilms leaving coils clean at a microscopic level

* Designates “Generally Recognized as Safe” as a food additive by the FDA.